High-pressure fuel pumps are important components in the latest internal combustion engines with the main function of delivering fuel. They create the pressure needed to spray fuel for combustion and hence improve the engine power, fuel consumption, and emissions. The hpfp n54 engine keeps fuel pressure steady. Being that high-pressure fuel pumps are so vital to the function of an engine, their installation must be done correctly to ensure the long life of the engine.

Proper Installation of an Operating System

High-pressure fuel pump installation is not just about tightening the pump to the required standard but. It is a set of processes to ensure that the pump runs efficiently within the system of the engine. Even the slightest variation in the right installation process can cause severe problems such as engine backfires, poor performance, and worst of all, a complete engine blowout.

Ensuring Correct Alignment

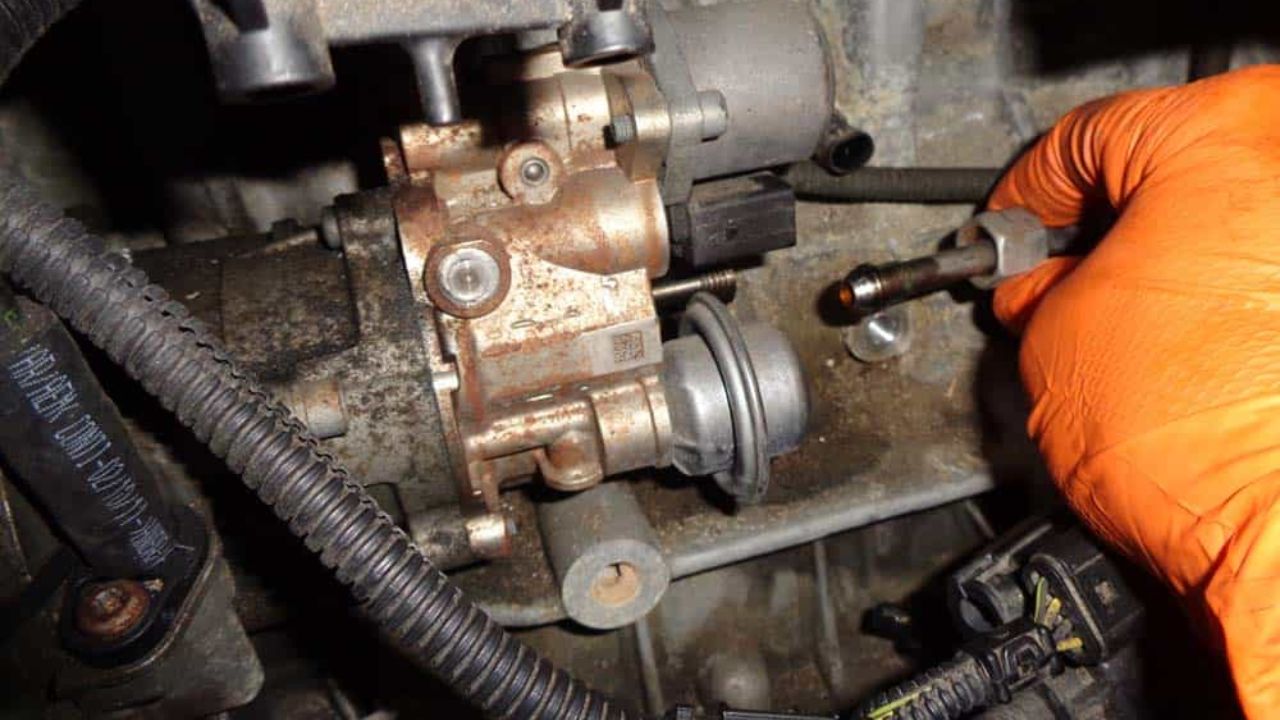

Another important consideration when installing a high-pressure fuel pump is the alignment of the same. If the alignment is incorrect, then the components of the pump are worn out unevenly, and this results in premature failure. Technicians need to install the pump with the help of highly accurate tools and according to the guidelines provided by the manufacturers. This alignment means that the pump’s internal components move in harmony without undue stress or friction being applied to them.

Securing Proper Sealing

High-pressure fuel pumps work under high pressure, and therefore, sealing should be done appropriately to avoid fuel leaks. Leakages also affect the fuel consumption and are also dangerous to the safety of vehicles. Proper sealing is always crucial and requires the right gaskets, O-rings, and sealing compounds that are recommended by the manufacturer of the specific equipment. Substandard or wrongly selected sealing materials may not be able to withstand the pressure causing fuel to leak and even cause damage to the engine.

Avoiding Common Installation Mistakes

High-pressure fuel pumps are also another area where even experienced technicians can make some mistakes during their installation. There are pitfalls that one should avoid to ensure that an installation is successful and here are some of them.

Ignoring Manufacturer Instructions

Manufacturers give clear and elaborate instructions on how to install something for a reason. The following instructions are given to make the pump to function effectively and safely. This means that if one decides to skip steps or completely ignore these instructions, he or she will have to deal with installation errors. In this case, technicians must always adhere to the laid down procedures regardless of the number of similar installations they have undertaken in the past.

Failing to Prime the Pump

Another common mistake is not to apply the priming of the pump before installation of the device. Pump priming makes sure the pump is full of fuel and is in a position to work as soon as the engine is started. In case there is no priming, the pump will draw air initially, which may cause internal damage and the pump’s life cycle will be short. This should not be the case and proper priming procedures should be followed to prevent this.

Conclusion

The installation process of the high-pressure fuel pumps must be done in the right manner. Every aspect is critical starting from the right positioning of the cover and its correct installation to the wrong mistakes that one can make. Going for professional installation can also help to increase the durability and effectiveness of the pump to help increase the reliability of the engine. Thus, vehicle owners can reap the full benefits of their high-pressure fuel pumps by following the best practices highlighted above and preventing future expensive engine complications.