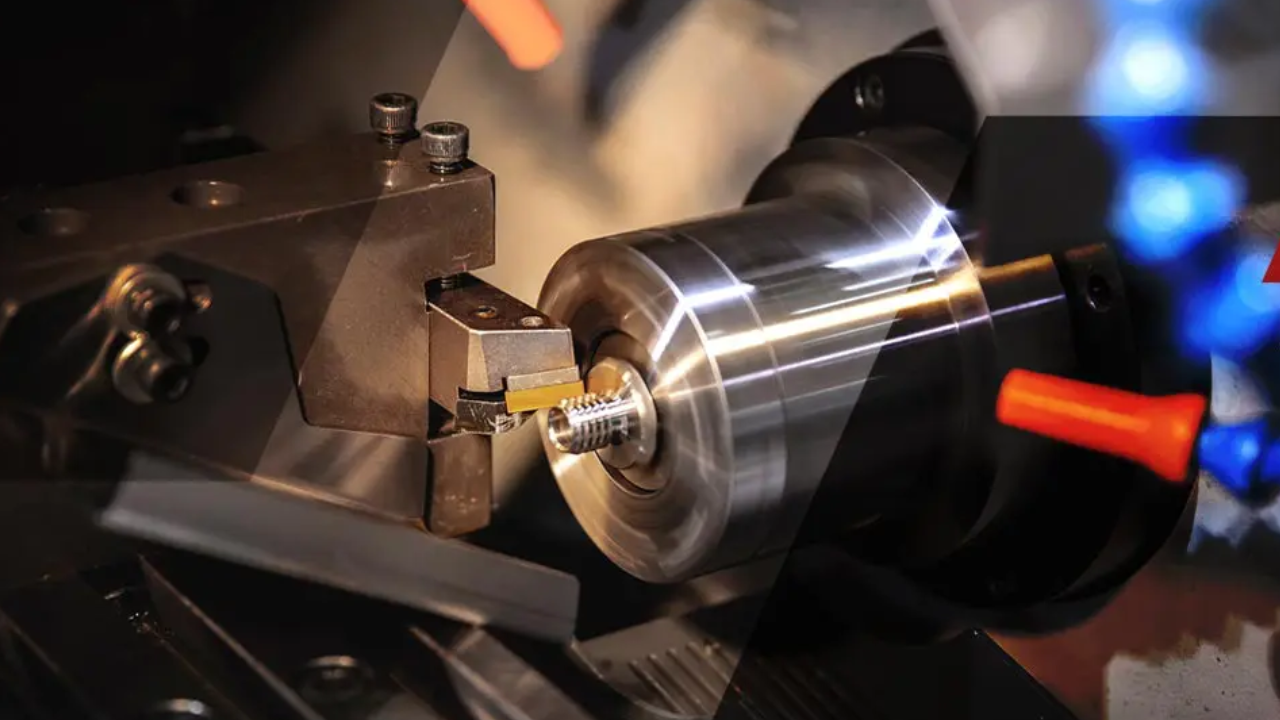

The quality and texture of a machined surface created by Computer Numerical Control (CNC) turning, milling, or other machining operations is referred to as CNC surface finish. Enhancing the part’s usefulness, appearance, and performance all depends on achieving the appropriate surface finish. The roughness average (Ra) or other metrics that indicate the smoothness or roughness of the surface are used to measure the surface finish.

Precision control over the cutting tools and toolpath made possible by CNC machining enables producers to produce a broad range of surface finishes, from rough to mirror-like. Surface finish is influenced by several factors, including material qualities, feed rates, cutting speeds, and tool selection. The best possible cnc surface finish for a range of applications is ensured by optimizing these settings.

How Does CNC Surface Finish Depend On Cutting Parameters?

CNC surface finish is significantly impacted by cutting parameters such as depth of cut, feed rate, and cutting speed. The best modifications strike a compromise between producing a smooth surface and removing material. Rough surfaces can result from extremely conservative parameters, and higher cutting rates can deflect the tool. To achieve the required surface quality in CNC machining, fine-tuning these parameters is essential.

Surface Is Finish Crucial For CNC Machining

For several reasons, surface smoothness is important when using CNC (Computer Numerical Control) machining.

Effect on Part Performance:

The functional performance of machined parts is directly impacted by surface finish. A smooth surface finish lowers friction, wear, and heat generation in situations where friction is a crucial element, like bearings or sliding components. Consequently, this improves the components’ longevity and efficiency.

Correlation with Precision:

Surface finish and the precision of machined components are closely related. Precision is the distinguishing feature of CNC machining. A well-polished surface shows that the CNC machine successfully converted the design requirements into the finished product. This is particularly crucial in sectors where precision is essential, including the aerospace and medical industries.

Function in Increasing Aesthetics:

Surface finish plays a major role in enhancing the machined components’ aesthetic appeal in addition to their utility. Customers’ perceptions are greatly influenced by aesthetics in sectors including design, consumer electronics, and automobiles. A perfect surface polish brings out the best features of the goods and makes a good first impression on customers.

Impact on Material Selection:

There is a wide range of materials available for CNC machining, and the required surface finish frequently affects the choice of materials. While certain materials have a smoother finish by nature, others might need more post-processing to provide the right surface quality. Optimizing the machining process requires an understanding of these interactions between material and surface finish.

Importance for Reduced Friction and Wear:

Achieving the proper surface finish is crucial in applications where low friction and minimal wear are required. Well-finished surfaces minimize adhesion and abrasion risks, increasing component longevity and lowering the need for routine maintenance.

Surface Finish and Coating Compatibility:

The compatibility of machined parts with different coatings is intimately related to surface finish. A few surface treatments help coatings adhere more readily, improving lubrication, corrosion resistance, and overall performance. When preparing for following coating operations, engineers and manufacturers need to take surface finish criteria into account.

Impact on Cost and Efficiency:

Although obtaining a higher surface polish could require extra machining operations or specialized equipment, doing so might result in long-term financial benefits. Superior surface finishes on components frequently result in lower post-processing requirements and rejection rates, which boost total production efficiency.

Customer Happiness and Market Competitiveness:

In the cutthroat market of today, customer happiness is critical. Perfectly finished machined parts not only fulfill functional specifications but also surpass client expectations. Manufacturers may be positioned as leaders in their sector as a consequence of favorable reviews, recurring business, and a solid reputation in the marketplace.

Last Summary

In CNC machining, surface quality is crucial because it affects material selection, performance, and appearance. Its effect on wear, friction, and coating compatibility highlights how important it is to improve the lifespan and effectiveness of components. Achieving the ideal surface quality is not just a technical requirement but also a strategic imperative for manufacturers striving for excellence in precision engineering.